THE CHALLENGE

Manufacturing facilities often have complicated and specialized machinery and equipment that require trained engineers to configure and look after them. Often, they are supplied by various vendors and if one-part stops functioning it can cause the whole production line to grind to a halt, which results in huge delays and losses.

During the recent worldwide pandemic, we saw that on-site employees are not available due to isolation requirements and the site may lose the necessary workforce required to resolve unforeseen challenges. In such situations, secure remote accessibility and management become essential. Therefore, professional industrial networking equipment is a must to connect these machines and provide remote management, while ensuring the security and reliability of the internet connection.

THE SOLUTION

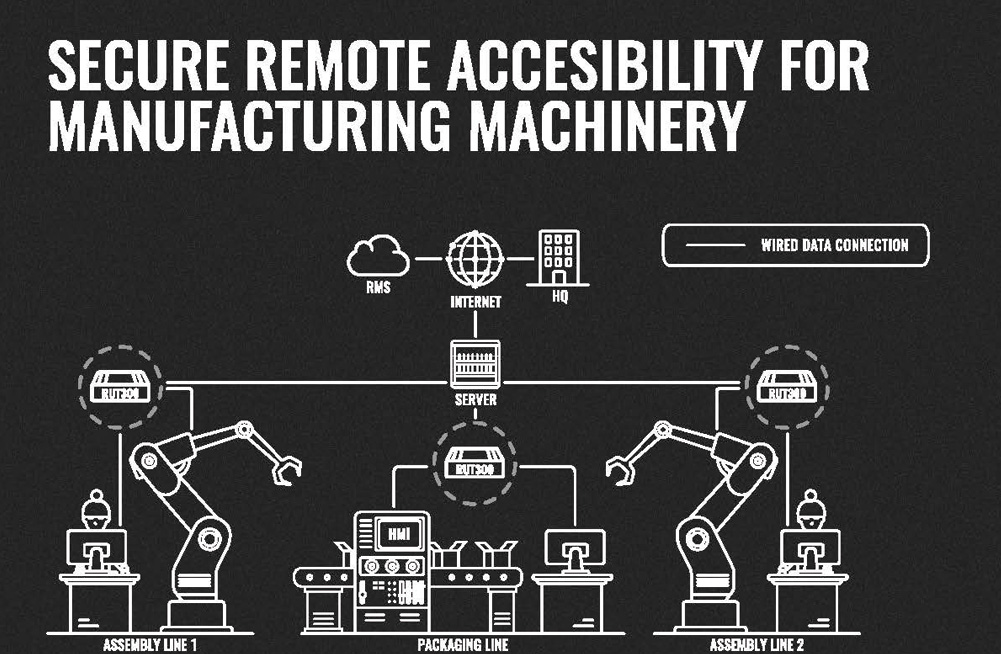

One of the biggest benefits of connecting the manufacturing machinery to the network is the ability to collect data. The Teltonika RUT300 industrial Ethernet router solves this problem as it has five Ethernet ports, two configurable digital Inputs/Outputs, and a USB to easily connect the various equipment and computers to the internet. A pre-configured firewall ensures the security of the solution from the very start and multiple top-rated VPNs provide data encryption.

A broad interval of supported power voltages makes this product suitable for a wide range of electronic equipment. Its rugged industrial design with a wide range of tolerated temperatures and vibration resistance makes this device durable and easily applicable in various settings.

One of the biggest benefits of this solution lies in the Remote Management System (RMS). While RMS Management allows for remote access to RUT300 for updates and maintenance, RMS Connect enables one to do the same with the machinery behind the router. This means that an engineer does not have to be present in a manufacturing facility to be able to configure, troubleshoot and manage the equipment. It’s also possible to set-up Events Reporting where an email is sent out after a specific event occurs as listed in pre-configured rules.

THE BENEFITS

- Remote Accessibility – RMS Connect allows one to reach, configure, and provide maintenance for a complete solution.

- Security – pre-configured Firewall for immediate use and multiple VPN protocols to choose from.

- Industrial design – the device supports multiple industrial protocols, is made of a rugged aluminum housing, I/Os, supports wide range of power supply voltages.

- Event reporting – notifies whenever anything goes out of the ordinary as per pre-set rules to resolve issues as fast as possible and reduce the possible harm to the ecosystem.

- Data collection – for monitoring, analytics, optimization, and event prediction.

Are you interested in remote access for your manufacturing machinery? We are ready to help you plan and implement remote access to streamline and evolve your business. Please contact us at saadique.mentor@poynting.co.za or 012 657 0050.